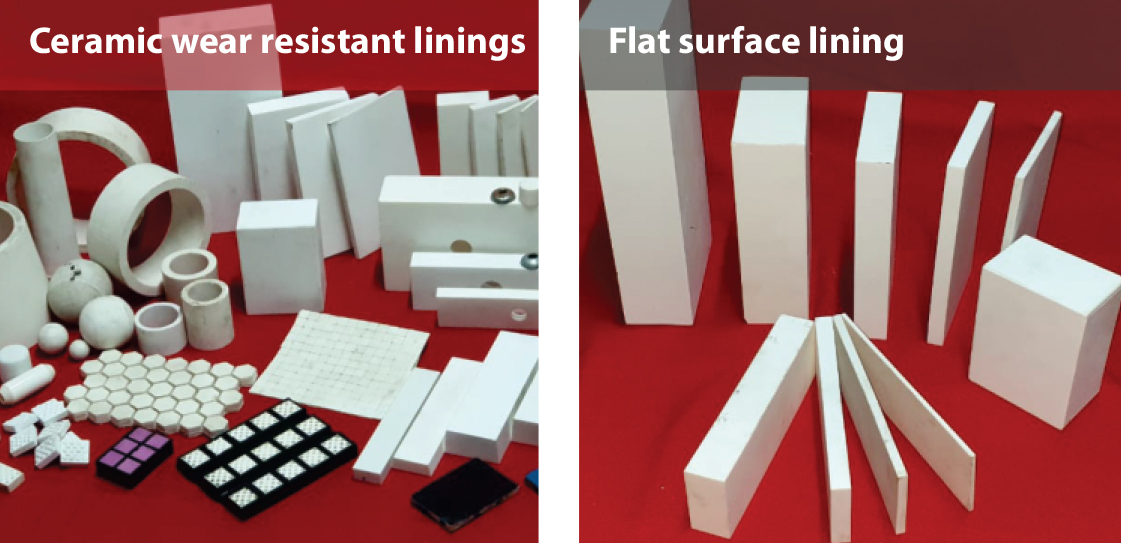

Ceramic & Wear Lining

Since March 2013, Fish Eagle Mining Solutions Pty (Ltd) has been a trusted supplier of both locally manufactured and imported ceramic and wear lining products,

sourced from some of the world’s leading ceramic manufacturers. We take pride in distributing and utilizing these top-quality products.

Over the years, we have built a solid reputation for excellence and professionalism, consistently striving to meet—and exceed—industry standards. This commitment has fostered sustainable and long-lasting business relationships with our clients.

Our team comprises technically skilled and highly dedicated personnel, some with over 20 years of experience. Together, we deliver value-added solutions tailored to your needs, backed by a competitive pricing structure.

Industries Served

- Mining

- Iron and Steel

- Power Generation

- Cement and Lime Manufacture

- Mineral and Benification

- Base and Precious Metal Smelting

- Petro-Chemical Refining and Production

Installation

Fish Eagle Mining Solutions Pty (Ltd) offer full on-site as well as in-house installation on all our wear protection products & services.

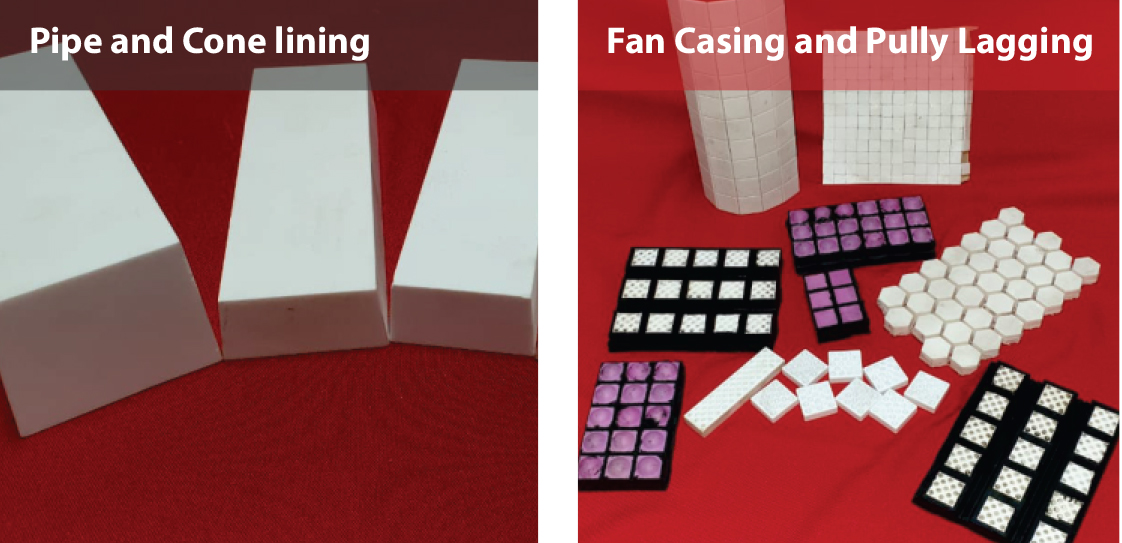

Chutes | Launders | Cones | Cyclones | Mills | Pipes | Pipe bends | Pully’s | Spoons | Square to rounds and a variety of other components.

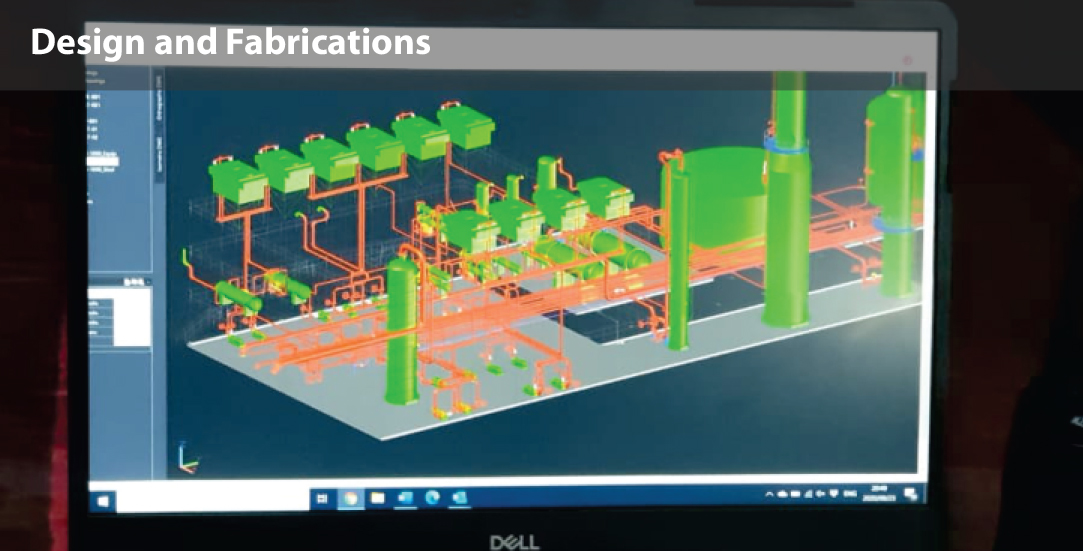

Designing and Fabrication

Fish Eagle Mining Solutions Pty (Ltd) has the capacity to design and Fabricate different types of components for plants and products. Lining of cyclones according to client specification or recommendations.

Flowliners

UHMWPE (Ultra-High Molecular Weight Polyethylene) is an engineering plastic and is a strong wear resistant material with a low friction co-efficient, outstanding chemical resistance, and corrosion prevention. It is light weight, 8 times lighter than steel, and environmentally friendly as it is recyclable, making it an ideal solution for lining chutes, hoppers, bunkers and silos. Professionally installed FLOWLINE can be relatively maintenance free, extending the working life of material handling plants.

Various installation methods offer a range of cost-effective solutions from simple bolting to rubber backed stick in type liners, space frame construction and even welded FLOWLINE drop in liners for fabricated chutes. With an exceptionally low friction co-efficient and zero water absorption, FLOWLINE linings are widely used to eliminate caking, bridging and hanging up of a variety of bulk materials in application extending through steel and cement production, mining and power generation. In new applications the use of FLOWLINE liners facilitates shallower chute and hoper angles providing greater design freedom, whilst in existing installations, the simulation of steeper angles through a low friction co-efficient is often the solution to plant blockage problems.

Excellent lining for trucks and railroad car cargo troughs, silo facilities, vibrating conveyor troughs, or slides and screw conveyors. For all applications with bulk materials, such as stones, ores, coal, cement, asphalt or food, there is a compatible model to replace steel.

Range variety covers the following properties:

- Anti-Static and Flame Retardant

- Improved wear resistance, Absorbs Vibrations, Impact & Expansion, Noise Reduction

- Temperature up to 110°C, Impact Resistance, Outstanding Sliding Property

- Two-Colored Sheets to indicated replacement

- Economical Alternative: Good Wear, Bending & Sliding ability for use on Soil, Coal and Wood Shavings

Selection of the lining

Sheets are available from 6mm to 100mm thickness, Variety of grades with specific uses and various colors. The plastic sheet selection is based on criteria such as bulk material, flowability, particle size, moisture content and the design of the funnel shape.

Adhesives and Epoxy Based Products

- Tile adhesive

- Epoxy wearing compound ( Ceramic | Steel)

- and Other adhesives (Silicone | Gel Coate)

Interested? Don't hesitate contact Us today!

Contact Us

Tel: 082 857 5830

Fax: 086 653 5549

E-Mail: info@fems.co.za

Follow Us